Coating

Coating

Corrosion prevention of pipes refers to measures to slow down or prevent corrosion and deterioration of pipes under the chemical or electrochemical action of the internal and external media or by the metabolic activities of microorganisms.

Why do seamless steel pipes need to be anticorrosive?

Seamless steel pipe is a relatively high-end steel pipe. After all, the raw material is iron, which will also rust, which will affect the service life in the pipeline. Therefore, the anticorrosion of seamless steel pipe is also a process that must be done before pipeline construction. For seamless steel pipe It is mainly used for 3pe anticorrosion or epoxy coal tar anticorrosion.

Seamless steel pipe anti-corrosion process

The anti-corrosion of the steel pipe is according to the requirements of the drawings, and the epoxy coal tar paint is used to wrap the glass cloth, and the top paint is coated for anti-corrosion.

Outer wall construction process: pipeline derusting → primer coating → first pass top coat → second pass top coat → wrap glass cloth → top coat → top coat;

Inner wall construction process: pipeline derusting→primer coating→first pass top coat→second pass top coat→third pass top coat

Anticorrosive technology of spiral steel pipe

In the process of anti-corrosion spiral steel pipe, there are two-cloth and three-oil anti-corrosion, that is, three times of epoxy coal tar anti-corrosion paint and two layers of glass cloth. People are also used to call three-oil and two-cloth anti-corrosion spiral steel pipe. The following is the anti-corrosion process.

Primary treatment-primer-first application-applique-second application-second application-third application-fourth application-inspection and supplement.

Anti-corrosion construction site

Anticorrosive spiral steel pipe note:

1. The timing of applying the cloth can be done after the paint is dried, or it can be applied immediately after the paint is applied. It should be treated according to specific coatings.

2. The brushing interval should be adjusted according to the drying time of the seasoning. The drying time of various coatings is different.

3. The direction of each brushing should be perpendicular to the direction of the last brushing, that is, cross brushing.

Steel pipe anticorrosive material

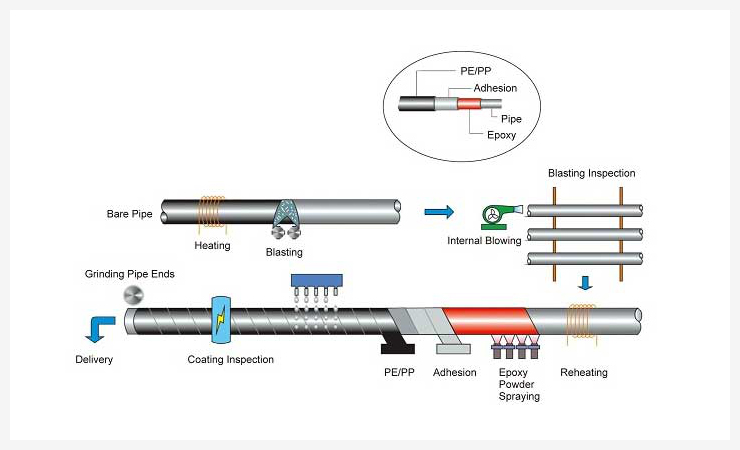

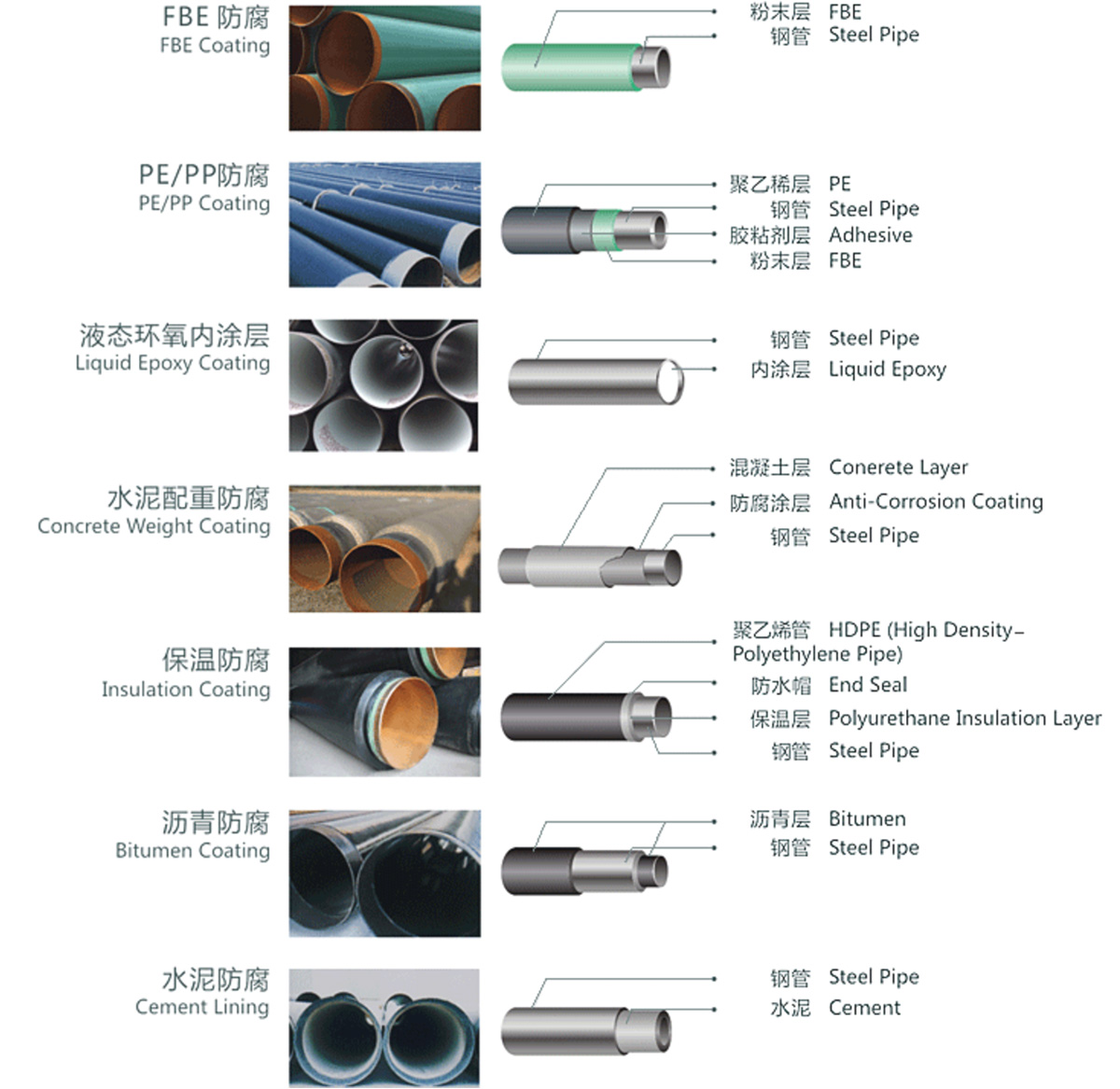

Anticorrosive pipeline materials mainly include 2/3P anticorrosion (polyethylene), 2/3PE anticorrosion (polypropylene), single layer epoxy powder anticorrosion, epoxy coal tar anticorrosion, etc. Anti-corrosion form of outer wall of steel pipe 3PE anticorrosion generally consists of 3 layers: One layer of epoxy powder (FBE>100um) Two-layer adhesive (AD) 170~250um Three-layer polyethylene (PE) 1.8~3.7mm 3PE anticorrosive steel pipe 3PE anticorrosive steel pipe base materials include seamless steel pipes, spiral steel pipes and straight seam steel pipes. The three-layer polyethylene (3PE) anticorrosive coating has been widely used in the petroleum pipeline industry due to its good corrosion resistance, water vapor permeability and mechanical properties. The anti-corrosion layer of 3PE anti-corrosion steel pipe is very important to the life of buried pipelines. Some pipelines of the same material will not corrode after being buried in the ground for decades, and some will leak in a few years. It is because they use different outer anti-corrosion layers. |

In actual operation, the three materials are mixed and integrated, and processed to form an excellent anti-corrosion layer firmly combined with the steel pipe. The processing method is generally divided into two types: winding type and round mold covering type.

3PE anti-corrosion steel pipe coating is (three-layer polyethylene anti-corrosion coating), which is a new kind of anti-corrosion produced by cleverly combining 2PE anti-corrosion coating in Europe and epoxy powder anti-corrosion steel pipe coating (FBE) widely used in North America Steel pipe coating. It has been recognized and used all over the world for more than ten years.

The coating of 3PE anticorrosive steel pipe is the epoxy powder anticorrosive coating between the bottom layer and the surface of the steel pipe, and the intermediate layer is a copolymer adhesive with branch structure functional groups. The surface layer is a high-density polyethylene anticorrosive coating.

3PE anticorrosive coating combines the high impermeability and mechanical properties of epoxy resin and polyethylene materials. So far, it has been recognized globally as a pipeline anti-corrosion coating with good use effect and high performance, which has been applied in many projects.

Advantages of 3PE anticorrosive steel pipe:

1. PE anticorrosive pipeline has extremely high sealing performance, long-term operation can greatly save energy, reduce costs and protect the environment.

2. Strong corrosion resistance, simple and quick construction, and the service life can reach 30-50 years.

3. It also has good corrosion resistance and impact resistance under low temperature conditions, and the PE water absorption rate is low (less than 0.01%).

4. At the same time, it has high epoxy strength, low water absorption of PE and good softness of hot melt adhesive. It has high anti-corrosion reliability. The disadvantage is that compared with the cost of other splicing materials, the cost is high.

Epoxy powder dipping anticorrosion process

Epoxy powder has always been applied by electrostatic spraying. Since the epoxy powder dipping process is troubled by adhesion problems, the dipping of epoxy powder has never been promoted. In recent years, with the successful development of the special phosphating solution for epoxy powder dipping, the epoxy powder dipping process has overcome the adhesion problem for the first time, and the emerging process of epoxy powder dipping has begun to be promoted.

Anti-corrosion construction

Construction principles

The quality of coating construction has a great influence on the performance of the coating. In the actual coating process, there are many examples of failure to achieve the expected anti-corrosion effect due to improper construction methods. In particular, many anti-corrosion coatings with excellent performance are extremely sensitive to the construction method, and only when they are constructed strictly in accordance with their respective construction conditions can they form a normal coating and achieve the expected anti-corrosion protection effect.

1. The substrate must undergo strict surface treatment

The steel base material must undergo derusting and degreasing treatment, and the phosphating treatment can be determined according to specific conditions.

2. To ensure the necessary coating thickness

The thickness of the anti-corrosion coating must exceed its critical thickness in order to play a protective role, generally 150μm ~ 200μm.

3. Control environmental factors such as temperature and humidity at the painting site

The indoor coating temperature should be controlled at 20℃~25℃; the relative humidity varies depending on the variety, generally around 65% is appropriate. There should be no wind, sand or drizzle during outdoor construction, the temperature should not be lower than 5℃, and the relative humidity should not be higher than 85%. Frost, dew, rain, and falling sand and dust on the incompletely cured coating should be avoided.

4. Control the coating interval time

If the primer is left for too long before the topcoat is applied, it will be difficult to adhere and affect the overall protective effect.In addition, the training of construction personnel and construction quality management must be strengthened. The construction personnel are required to understand the nature, usage, construction points and technical requirements of the coating.

Managers must strengthen quality control to ensure that each process meets the technical requirements in order to finally obtain an excellent anti-corrosion coating. It is also necessary to strengthen labor safety protection, pay attention to solvent volatilization, and strengthen ventilation to avoid poisoning.

Cutting

Cutting

Before Cutting Pipe and Tubing

No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting.

After Cutting Pipe and Tubing

Unless a cut is perfectly clean, you should expect to remove burrs from around the edge, especially after sawing.

Use a deburring tool to clean the edge after tube cutting.

You may opt to use a metal file on the cut of a metal pipe.

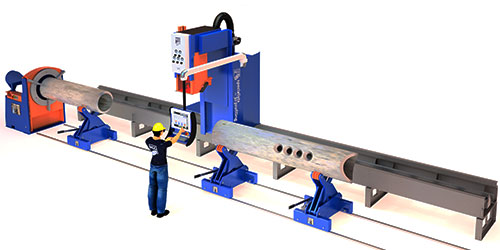

CNC Pipe Cutter--ProCutter 600–900

Our CNC Pipe Cutters, ProCutter 600 and 900, incorporate all of HGG’s advanced technology and expertise. Operational excellence is applied to keep costs low. They come with oxy-fuel, plasma, marking and CAD-CAM Interfaces.

Pipe Cutting Machine; chuck type--SPC 500–1200 PT

The SPC 500–1200 Stationary Pipe Cutting Machine is able to process a wide variety of materials, sizes and wall thicknesses making it suitable for all kinds of applications. It comes with oxy-fuel, plasma, marking and CAD-CAM interfaces.

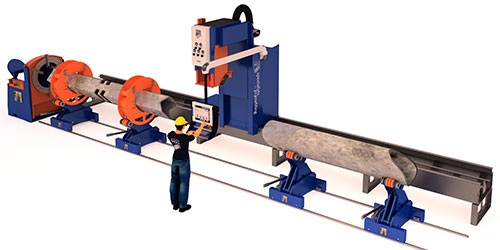

Pipe Cutting Line; roller bed type with floating chuck--SPC 660–1200 RB

The SPC 660–1200 RB Pipe Cutting Line from HGG combines the roller bed principle for an uninterrupted material flow while controlling the rotation of the material with a floating chuck registering linear displacement.

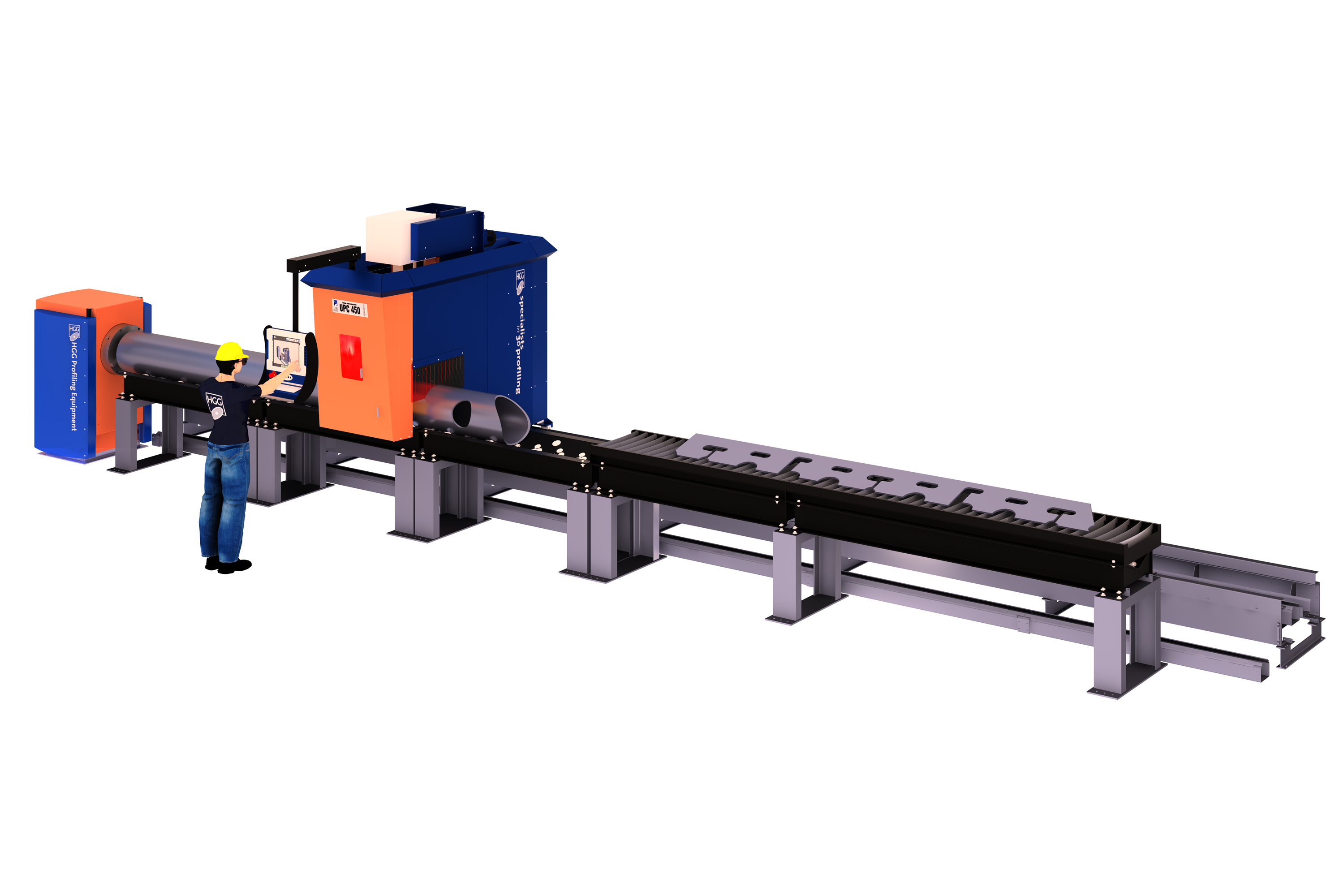

Pipe and Box section Cutting Machine--MPC 450 I 500–1200

Pipe and square tube cutting machine for automated 3D pipe and box cutting. The MPC is highly accurate and versatile and combines three machines into one.

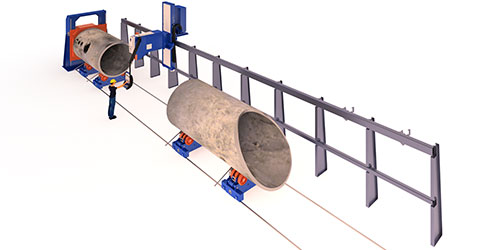

CNC Pipe Cutting machine for vessels and offshore--SPC 1500–3000 PT

The SPC 1500–3000 CNC Pipe Cutting Machine is a very robust machine built to handle large pipe diameters and heavy weights. Everything in the machine is designed and implemented with the purpose to guarantee extreme tolerances during cutting.

Pipe and Vessel Head Cutting machine--SPC 1500–3000 VC

The SPC 1500–3000 VC pipe and vessel head cutting machine is the answer to pressure vessel manufacturers struggling with and spending too much time on lay outs. The VHC saves you time on cutting, fitting and welding.

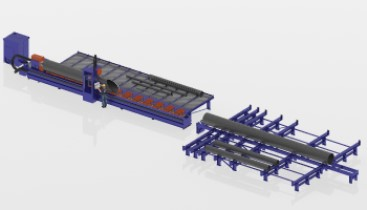

CNC Pipe Cutting Line; roller bed type--RBPC 660–2000

The RBPC 660–2000 is a highly productive CNC pipe cutting line driven by a roller bed. It comes with wheels sets and torch-to-material distance sensors dealing with pipe behavior during rotation.

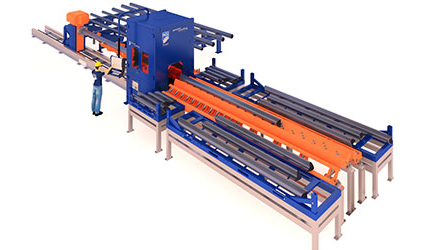

Pipe and Tube Cutting Line--TCL 400

The TCL 400 Plasma Pipe and Tube Cutting Line is the next generation 3D cutting machine for pipe and tube. The highly productive TCL is the answer to automated but expensive tube laser cutting machines.

Profile Cutting Machine--Ship Profiler

Our Ship Profiler offers automated profile cutting for an affordable price, combining high productivity with a small footprint.

Pipe profiler with rollerbed---ProCutter 900 RB

The ProCutter 900 RB is a pipe profiler which is logistically optimized. This affordable tube profiling machine is a true workhorse which incorporates all of HGG’s advanced technology and expertise. Operational excellence is applied to keep costs low.

Bending

Bending

With years of industry production experience and equipment upgrading, PMC Steel has proposed a new processing solution on the basis of the original production- Bending

What material is suitable for bending?

1. Carbon steel plate, that is, SPPC cold-rolled steel plate. SPCC cold-rolled steel plate is the most commonly used material in sheet metal processing, and is also the most easily realized material in sheet metal bending process. Because of its good ductility, it is especially suitable for sheet metal bending. In addition, since the SPCC plate needs to be surface treated later, the defects caused in the bending process can be covered up. It is the easiest material to bend.

2. Stainless steel plate, commonly used are SUS201, SUS304, SUS316, 1Cr17, etc. Because stainless steel has strong anti rust ability, it can be used in humid environment or outdoors without surface treatment. There are new requirements for sheet metal bending. Generally speaking, for the sake of perfect processing of sheet metal parts, the surface must be free of scratches and creases. During normal sheet metal bending, there is sliding friction between the sheet metal material and the bending lower die, which will form folds. This is not allowed for stainless steel materials.

3. Aluminum plate and copper plate. These two materials are somewhat similar to stainless steel. Generally, the surface is not allowed to be scratched or indented. There is another special point. It is easy to have cracks when bending. Red copper plate generally does not have cracks, yellow copper plate is poor, and many models of aluminum plate are prone to cracks when bent. This requires sheet metal bending masters to adopt different bending methods according to different situations.

4. Hot rolled steel plate. The above materials need to be operated by different bending processes due to their material properties. Hot rolled steel plate is the most afraid and difficult material in bending. The hot-rolled steel plate is also called SPHC, because a hard layer of ferric oxide will be formed on the surface during the rolling process.

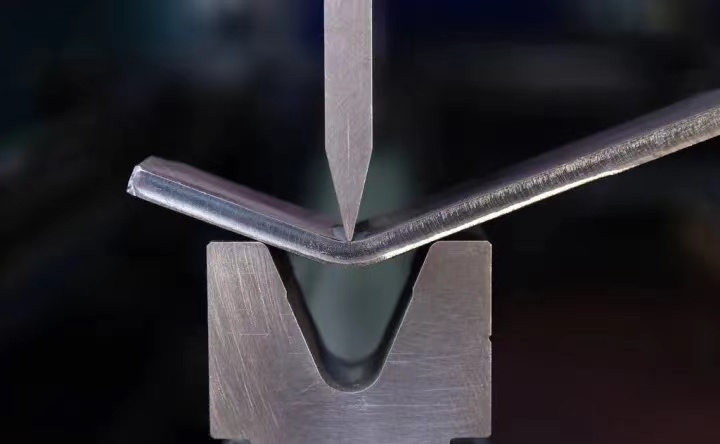

How to find the right bending method? There are many reasons that affect the bending effect. Such as plate, wall thickness, material, angle requirements and secondary processing requirements. Other reasons include throughput, bending efficiency, overhead costs, and special requirements for the sheet or sheet. To understand these details, which bending methods should we choose? Below are the cutting methods for you to choose from. (1) Free bending The free bending method is the most commonly used method. Free bending is to use the two edges at the opening of the die and the edge of the top of the punch to bend, and the bending angle is determined by the depth of the punch entering the die. The bending force required for free bending is small, the force on the mold is relatively moderate, and the service life of the mold can be extended. |

(2) Correction of bending Correction bending is the precision pressing of the rounded corners and straight edges of the workpiece by the punch. During the downward movement of the punch, the angle of the blank will be smaller than the angle of the punch, resulting in negative springback; at the end of the stroke, the punch and the punch will correct the blank so that the rounded corners, straight edges and bending radius are all close to the punch. . It can be seen that correcting the bending can effectively overcome the rebound effect, so that a high bending accuracy can be obtained. |

(3) Three-point bending To process this part with a CNC press, it only needs to compile a program and fix and position it once to complete the whole process. The programming time is two or three hours at most, the processing time is only a few minutes, and the processing accuracy is high. The pressure of the hydraulic pad is evenly distributed over the entire bending length, so that the bending force of the punch is evenly distributed over the entire bending length. Each punch is elastically supported, so it can automatically adapt to the bending straightness of the die and ensure a constant pressure distribution, thus improving the accuracy of the bending angle and the straightness of the edge of the bending angle. The bending angle error of the three-point bending method is ±15 degrees, which is equivalent to the accuracy of the corrected bending. The bending thickness can reach 20mm. When the thickness of the plate exceeds 3mm, the three-point bending method is the best method to obtain bending. This is because, in addition, in order to obtain the same bending accuracy, only corrective bending is used, but the bending force will exceed the pressure limit that the mold can withstand. |

End Machining

End Machining

-Pipe Threading-

Common pipe thread types:

1.NPT or NPS (national pipe tapered or straight): Most common in North America

2.MIP or FIP (male or female iron pipe): Same thread dimensions as NPT

3.BSP(T) or BSP(S) (British standard pipe tapered or straight): Most common in Europe

4.Compression: A unique threaded fitting that does not mate with other thread types

5.UNS (National Unified Special): Some compatible with compression fittings

NPT Thread Chart

NPT Nominal Size | Actual OD | Hand Tight Turns | Wrench Turns |

1/8 | 0.405" | 4.5 | 2.5 |

1/4 | 0.54" | 4 | 3 |

3/8 | 0.675" | 4.5 | 3 |

1/2 | 0.84" | 4.5 | 3 |

3/4 | 1.05" | 4.5 | 3 |

1 | 1.32" | 4.5 | 3.25 |

1 1/4 | 1.66" | 4.5 | 3.25 |

BSP Thread Chart

BSP Nominal Size | Major Diameter (OD) | Minor Diameter (ID) |

1/8 | 0.38" | 0.34 |

1/4 | 0.52" | 0.45 |

3/8 | 0.65" | 0.59 |

1/2 | 0.83" | 0.73 |

3/4 | 1.04" | 0.95 |

1 | 1.30" | 1.19 |

1 1/4 | 1.65" | 1.53 |

-Pipe Beveling-

What is pipeline beveled end and why use it?

In fact, it is processed prior to the welding of two pieces of line pipes, an angle formed at the edge of the end of the pipe with the help of a beveling machine. Beveling of pipe or tubing is most commonly used to prepare the ends for welding. It can also be used for deburring the cut ends for safety and aesthetic reasons.

Subtract the pipe’s wall thickness from the pipe’s outside diameter. For example, if you had a pipe with a diameter of six inches and a wall thickness of two inches, you would subtract two from six to get four.

Why bevel a pipe?

Beveling of pipe or tubing is most commonly used to prepare the ends for welding. It can also be used for deburring the cut ends for safety and aesthetic reasons.

Common types of beveled ends

Beveling ends can be made into various angles, achieving the better welding seam. Common beveled ends for butt joints are I—Type butt joint, single—V beveled end, double—V beveled end and single U—beveled end.

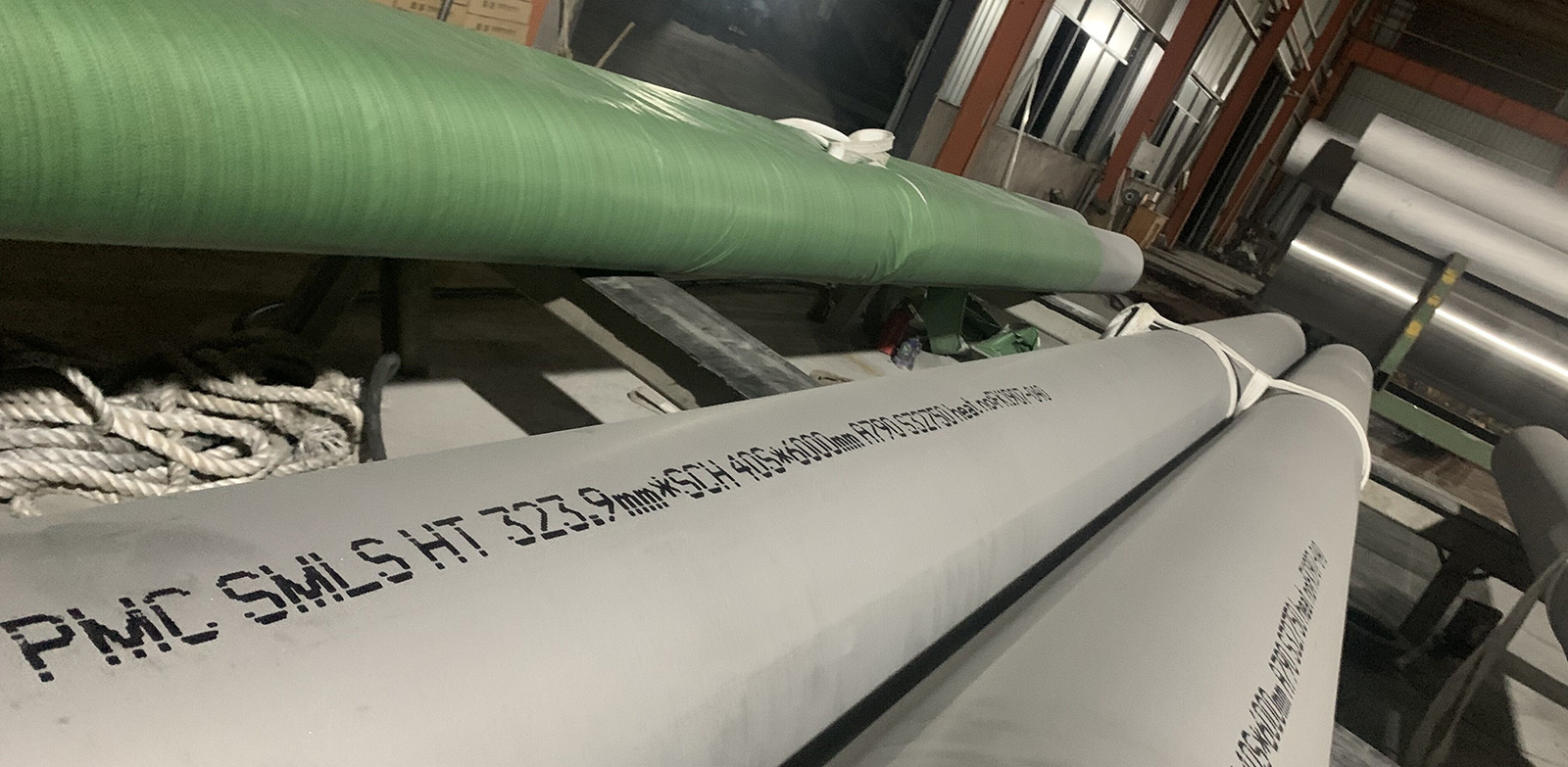

-Marking-

Finished Products Like Pipes/Tubes/Fittings/Bars are marked with Electric Etching/Electronic Inkjet Marking machine.

Each Product is marked with “Manufacturers Logo, Name, Size, Specification, Grade, Heat No. or as per Customer Requirements.

For example:

Marking Requirements of Seamless Steel Pipe

1. Manufacturer’s name or mark

2. Specification number (year-date not required),

3. Size (NPS and weight class, schedule number, or specified wall thickness; or specified outside diameter and

specified wall thickness),

4. Grade (A or B),

5. Type of pipe (F, E, or S),

6. Test pressure, seamless pipe only,

7. Nondestructive electric test, seamless pipe only.

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add