Carbon Steel Galvanized Pipe

Introduction

Because the pipes are galvanized, it is protected from rust and corrosion. Steel rusts after interacting with water or moisture in the air over time. By adding a coating of zinc to the tubing, galvanized steel round tubing corrodes much slower, extending the life of your tubing.

Standard

Galvanized steel pipe coating types | · Hot dipped galvanized steel pipe · Cold galvanized pipe or electric galvanized pipe · Zinc coated galvanized pipe · Powder coated galvanized steel pipe · Epoxy coating galvanized pipe · PVC coated galvanized pipe |

Standard | EN ISO 1461 |

Nominal diameter | 1/2" - 4" inches |

Nominal wall thickness | 2.0 mm - 4.5mm |

Test pressure index Dia | 10.2 mm - 168.3 mm 3 MPa 177.8mm - 323.9 mm 5 MPa |

Zinc coated galvanized pipe layer thickness | For Hot galvanized : 35μm - 650μm For Cold galvanized: 5-15μm |

Seamless galvanized carbon steel pipes process | · Finished pickling · washing · plating · drying · hanging plating · cooling · medicine · cleaning · grinding · and hot galvanized finish |

Types of Galvanizing coating appearance | · Shiny · Spangled · Matte grey · Shiny and dull |

Test Reports | Laboratory testing, magnetic gauge test reports |

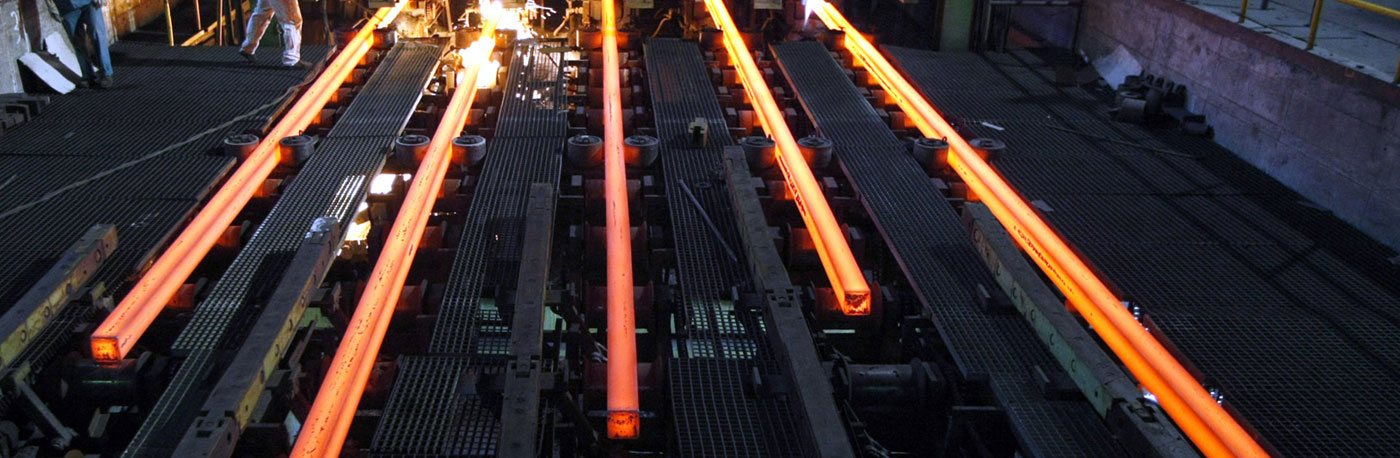

Manufacturing Process

Hot dip galvanizing process:

Workpiece degreasing → washing → pickling → washing → drying solvent dip fluxing preheated hot dip galvanized → cooling → finishing → rinsing → drying → passivation test

Cold-galvanized process:

Chemical degreasing → washing → hot water hot water electrolysis degreasing → washing → washing → strong corrosive galvanized iron alloy → washing → washing → light → → washing → drying passivation

Advantage

| - Galvanized pipe after being hot dip galvanized surface can be protected, and inside the cavity of the pipe or any other coating the corner is difficult to enter, deepen the zinc can easily cover to the top, make whole galvanized pipe can be protected. - After being galvanized pipe galvanized its impact resistance and anti-wear properties are very good, because the zinc coating hardness values larger than the hardness of steel, and therefore the impact resistance of hot-dip galvanized after and abrasion resistance is quite good. Furthermore galvanized biggest advantage is in the corner of the zinc layer will be relatively thick and good toughness and abrasion resistance, while other coatings are often in this corner of the thinnest most difficult construction, and therefore are vulnerable injury. - There is a major feature of hot-dip galvanizing that is occasionally subject to considerable mechanical damage or other causes a small portion of the zinc layer off, the iron-based nudity, then it will play around the zinc layer and other coatings not the same spirit of sacrifice to protect the steel here, so from erosion. - The hot-dip galvanizing and other aspects of life and aesthetics of art, life expectancy is in a particular environment, the main agency of the thickness of the coating, and the coating thickness of it but also by the thickness of the galvanized pipe and decisions, and therefore thicker galvanized pipe is more easily coating. Second, in terms of aesthetics and art, at the time it is certain severe corrosive environments, galvanized layer above Zaishi paint to deal with, as long as the selection of the correct paint system, easy construction of its anti-corrosion effect will be very good. |

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add