Casing &Tubing

Introduction

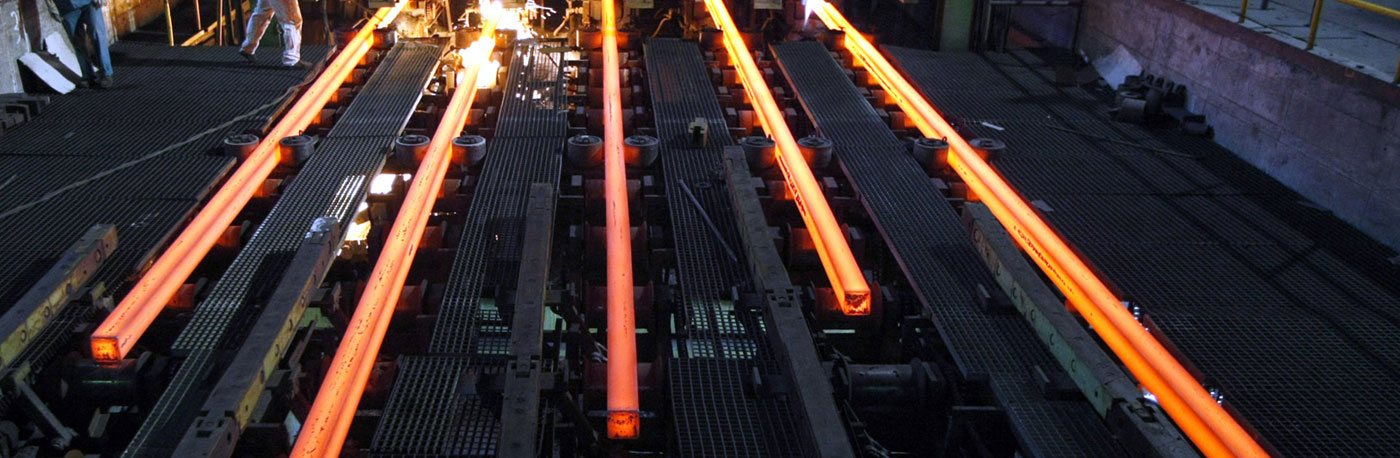

Casing is used for lining the complete borehole which has been dug into the ground to procure oil. Similar to the drill pipe, the oil well casing pipe is also subjected to axial tension, therefore they are required to be made from high-quality strong steel material. OCTG casing is large diameter pipe which are held in place in the borehole using cement.

The diameters of OCTG casing pipe range from 4.5″ to 36″. The well-cemented pipe acts as the structural component of the well and offer hole integrity. They prevent the well from collapsing when the drilling process is on. Good quality, well cemented casing can stay in place for the whole life of the well.

Product: | Casing Pipe, Oil Casing, API Casing, Well Casing, Casing |

Application: | Used for oil casing and tubing in oil wells as well as sidewall |

Size: | OD: 114.3mm-508mm |

WT: 5-16mm | |

LENGTH: R1, R2, R3 | |

Pipe Standard: | API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 | |

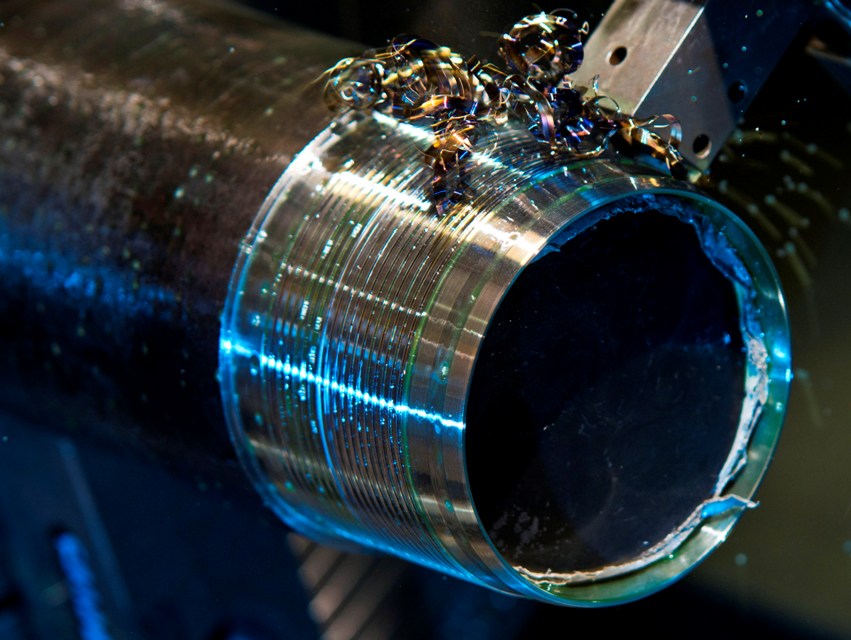

Thread: | NUE, EUE, VAM, STC, LTC, BTC, XC, VAM TOP, NEW VAM,HYDRILL CS |

Special Service | Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

Accessories: | Pup Joint, Coupling, Drill Collar, Crossover etc. |

Tubing is inserted inside the wellbore through the oil well casing pipe, which helps the transportation of the hydrocarbons to the surface. It is pipe either used for transporting natural gas or crude oil to the facilities for further processing after the drilling is complete. Similar to the drill pipe and casing, tubing also is subjected to high pressure during the extraction process, and hence needs to be thick, strong and sturdy. Production tubing is available in various sizes ranging from ¾” to 4 ½”.

Product: | Tubing Pipe, Oil Tubing, API Tubing Well Tubing, Tubing |

Application: | Used for extracing Oil or Gas from Wells |

Size: | OD: 48.26mm-114.3mm |

WT: 3.18-16mm | |

LENGTH: R1, R2, R3 | |

Pipe Standard: | API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 | |

Thread: | NUE, EUE, VAM, STC, LTC, BTC, XC, VAM TOP, NEW VAM,HYDRILL CS |

Special Service | Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

Accessories: | Pup Joint, Coupling, Drill Collar, Crossover etc. |

Chemical Materials and Mechanical Properties

|

| C | Mn | Mo | Cr | Ni Max | Cu Max | P Max | S Max | Si Max | ||||

Min | Max | Min | Max | Min | Max | Max | ||||||||

H40 | - | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

J55 | - | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

K55 | - | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

M65 | - | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

L80 | 1 | - | 0.43 | - | 1.90 | - | - | - | - | 0.25 | 0.35 | 0.030 | 0.030 | 0.45 |

L80 | 9 Cr | - | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.0 | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

L80 | 13 Cr | 0.15 | 0.22 | 0.25 | 1.00 | - | - | 12.0 | 14.0 | 0.50 | 0.25 | 0.020 | 0.010 | 1.00 |

C90 | 1 | - | 0.35 | - | 1.20 | 0.25 | 0.85 | - | 1.50 | 0.99 | - | 0.020 | 0.010 | - |

P110 | - | - | - | - | - | - | - | - | - | - | - | 0.030 | 0.030 | - |

Q125 | 1 | - | 0.35 | - | 1.35 | - | 0.85 | - | 1.50 | 0.99 | - | 0.020 | 0.010 | - |

Note:If the wall thickness is less than 17.78mm, the molybdenum content of the C90-1 steel grade has no lower limit.

Dimension Tolerances:

Casing Pipe | Tolerance | |

Outside Diameter |

Pipe Body | D≤101.60mm,±0.79mm |

D≥114.30mm,+1.0%, -0.5%D | ||

Coupling | ±1%D | |

Wall Thickness | 0, -12.5%t | |

Weight | Single Lengths | +6.5%,-3.5% |

Carload Lots or Order Quantity | ≥18144 kg(40000ib),0,-1.75% | |

<18144 kg(40000ib),0,-3.5% | ||

Tensile and Hardness Requirements:

Steel grade |

Type |

Total elongation under load (%) |

|

min | Hardness max | ||

min | max | HRC | HBW | ||||

H40 | - | 0.5 | 276 | 552 | 414 | - | - |

J55 | - | 0.5 | 379 | 552 | 517 | - | - |

K55 | - | 0.5 | 379 | 552 | 655 | - | - |

N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 |

L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

L80 | 9 Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

L80 | 13 Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

P110 | - | 0.6 | 758 | 965 | 862 | - | - |

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add