Super-Austenitic Steel Pipe

Introduction

Seamless Stainless steel pipes are an iron alloy that contains a minimum of 10.5% chromium. Alloying elements such as nickel, molybdenum, titanium, carbon, nitrogen, and copper can boost the strength, formability, and other properties of stainless steel. Different alloys offer different levels of corrosion resistance.

Stainless steel alloys offer greater cryogenic toughness, a higher work hardening rate, increased strength and hardness, greater ductility, and a more attractive appearance compared to carbon steel.

Standard

ASTM A213 | Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes (1/8”-5”) |

ASTM A312 | Standard Specification for Seamless and Welded Austenitic Stainless Steel Pipes |

ASTM A269 | Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service |

ASTM A268 | Standard Specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service |

ASTM A270 | Standard Specification for Seamless and Welded Austenitic Stainless Steel Sanitary Tubing |

ASTM A249 | Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes |

ASTM A376 | Standard Specification for Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service |

ASTM A632 | Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service |

ASTM A789 | Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service |

ASTM A1016/A1016M | Standard Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes |

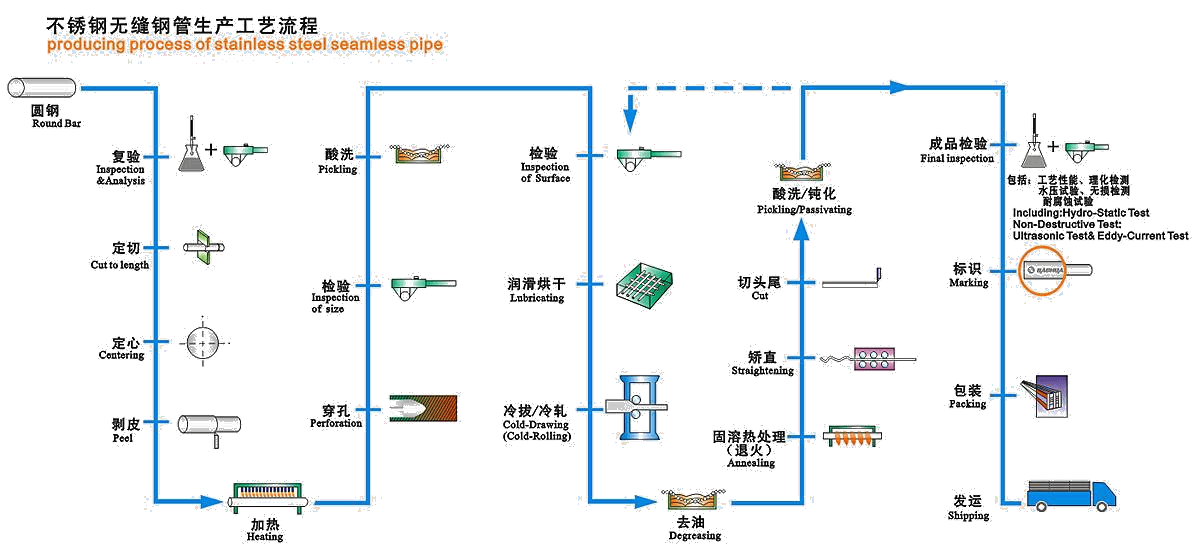

Manufacturing Process

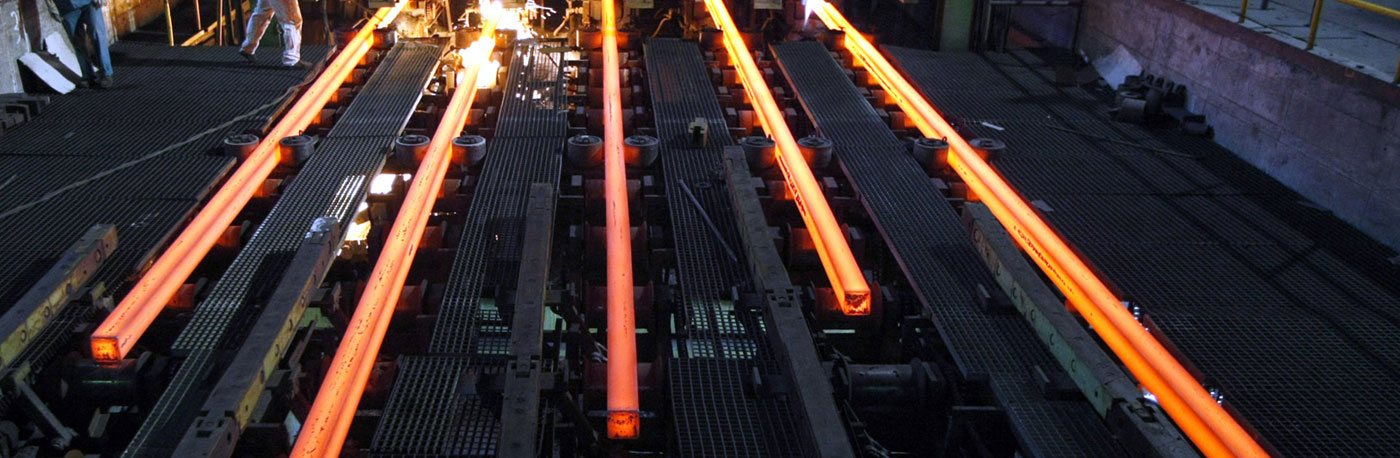

| Seamless stainless steel pipe is made from solid stainless steel bar which is called billet. By using different processing techniques such as extruding, gun drilling or piercing, the steel bars are produced to be steel tubes.

1. Firstly, the billets would be inspected exactly. 2. Then put the billets into the heat to raise the temperature. 3. The hot billets would then be pierced through the center with a mandrel. Through this procedure, the bar shape billet becomes hollow shape billet. 4. The next step is rolling and stretching the hollow billet. The billet is precisely rolled and stretched until it meets all the specifications with length, diameter and wall thickness according to requirements. |

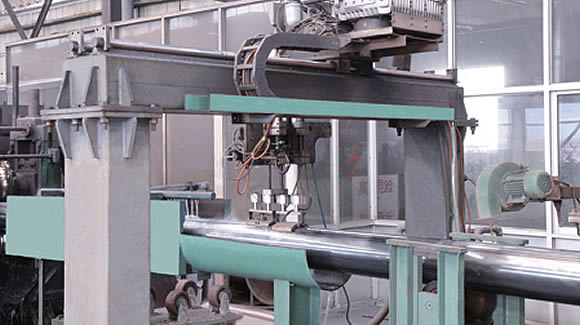

Inspection

Seamless stainless steel pipe should be manufactured to applicable standards and fully tested for potential defects before being prepared for shipment to the customer.

Hydrotest After the tube is fully formed to the desired specification it is hydrostatically tested to ensure integrity. Hydrostatic testing determines and verifies the tubing meets the specification. Several types of information can be obtained through this verification process. Key inspection data can be identified through the hydrotest process, such as: Material flaws Mechanical properties Specific hard spots that can fail when hydrogen is present Finishing Stainless steel coil tubing can be level wound on spools for shipment or straightened and cut to specific lengths designated by the customer. Products can be polished and stenciled with pertinent information for lot traceability and manufacturing identification. |

|

Application

| - Chemical plants

- Aviation fields |

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add