Carbon Steel Welded Pipe

Introduction

OD | 21.3mm -660mm |

W.T | 1mm-20mm |

LENGTH | 0.5mtr-22mtr |

Surface | Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement |

Standard | API5L, ASTM A53 GR.B, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217; API SPEC 5L ISO 3183 GB/T 9711.1 GB/T 9711.2 GB/T 9711.3 |

Ends | Square Ends (straight cut, saw cut) Beveled Ends |

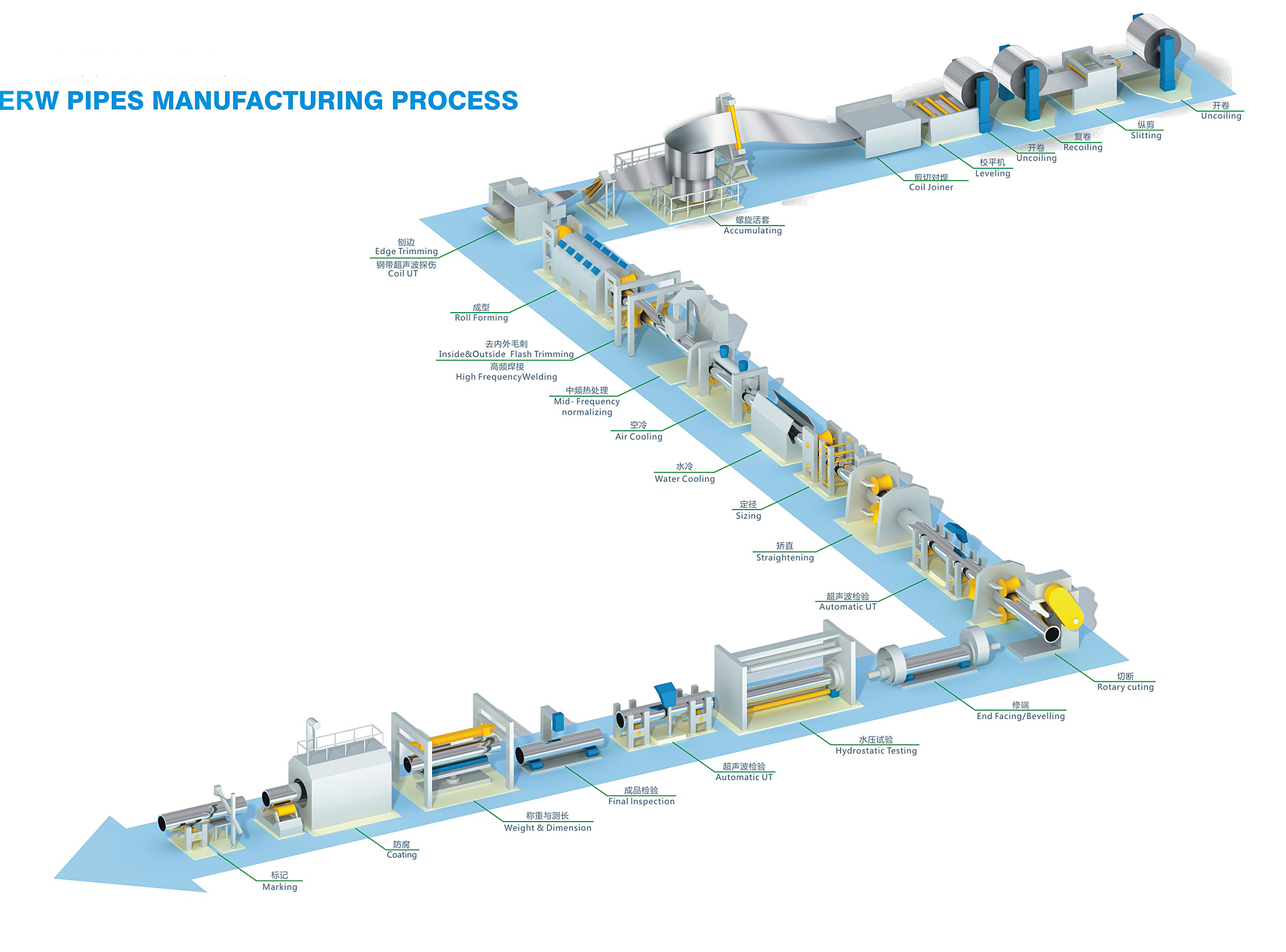

Manufacturing Process

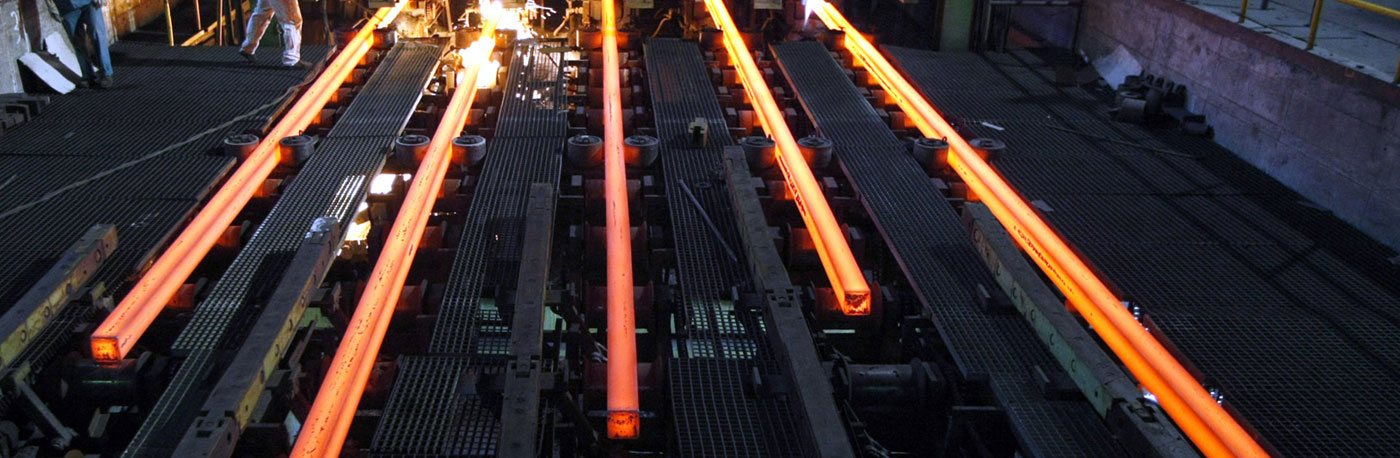

Electric Resistance Welded (ERW) pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then simultaneously heated with a high frequency current and squeezed together to form a bond. The longitudinal ERW seam does not require filler metal.

Facilities

Introduction

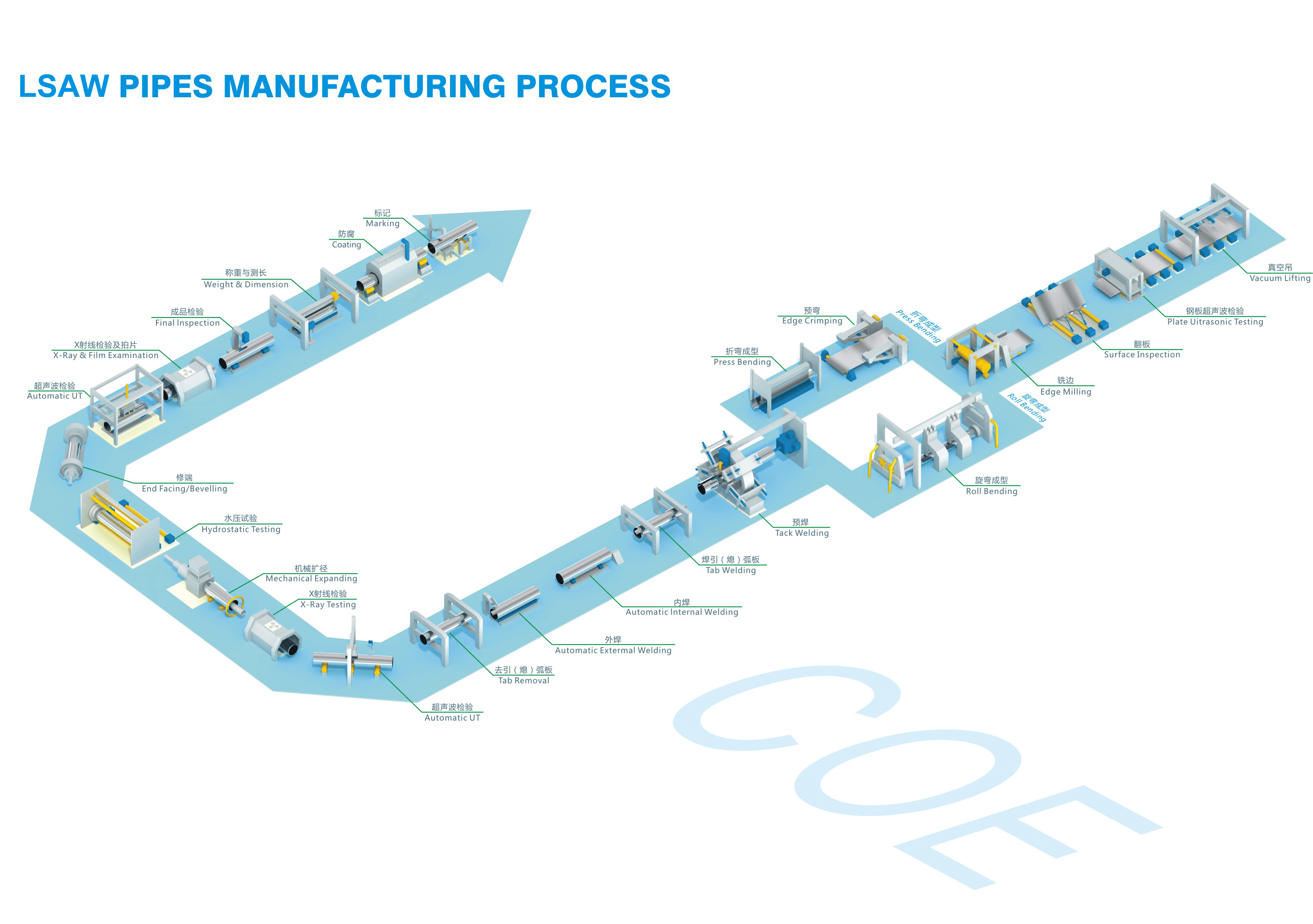

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction,petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

When compared UOE vs JCOE pipes, LSAW steel pipe manufacturers in China can produce more sizes as:

Outside Diameter:219mm-1625mm;

Wall Thickness: 6.35 mm – 60 mm;

Length: 2 m – 18 m

From this, we can see that the LSAW pipe having superiority. PMC Steel offers LSAW pipe with high quality, competitive prices, and best service.

Standard

ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

API 5L | Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

A252 | Standard Specification for Welded and Seamless Steel Pipe Piles |

A500 | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

A139 | Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) |

A672 | Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

A691 | Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures |

Types | Standard | |||||

SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

Tube end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm<t<15.0mm, ±0.11<="" p="" style="padding: 0px; margin: 0px; user-select: text !important;"> |

D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Manufacturing Process

| Plate edge milling machine |

Inspection

Chemical Component Analysis |

|

Introduction

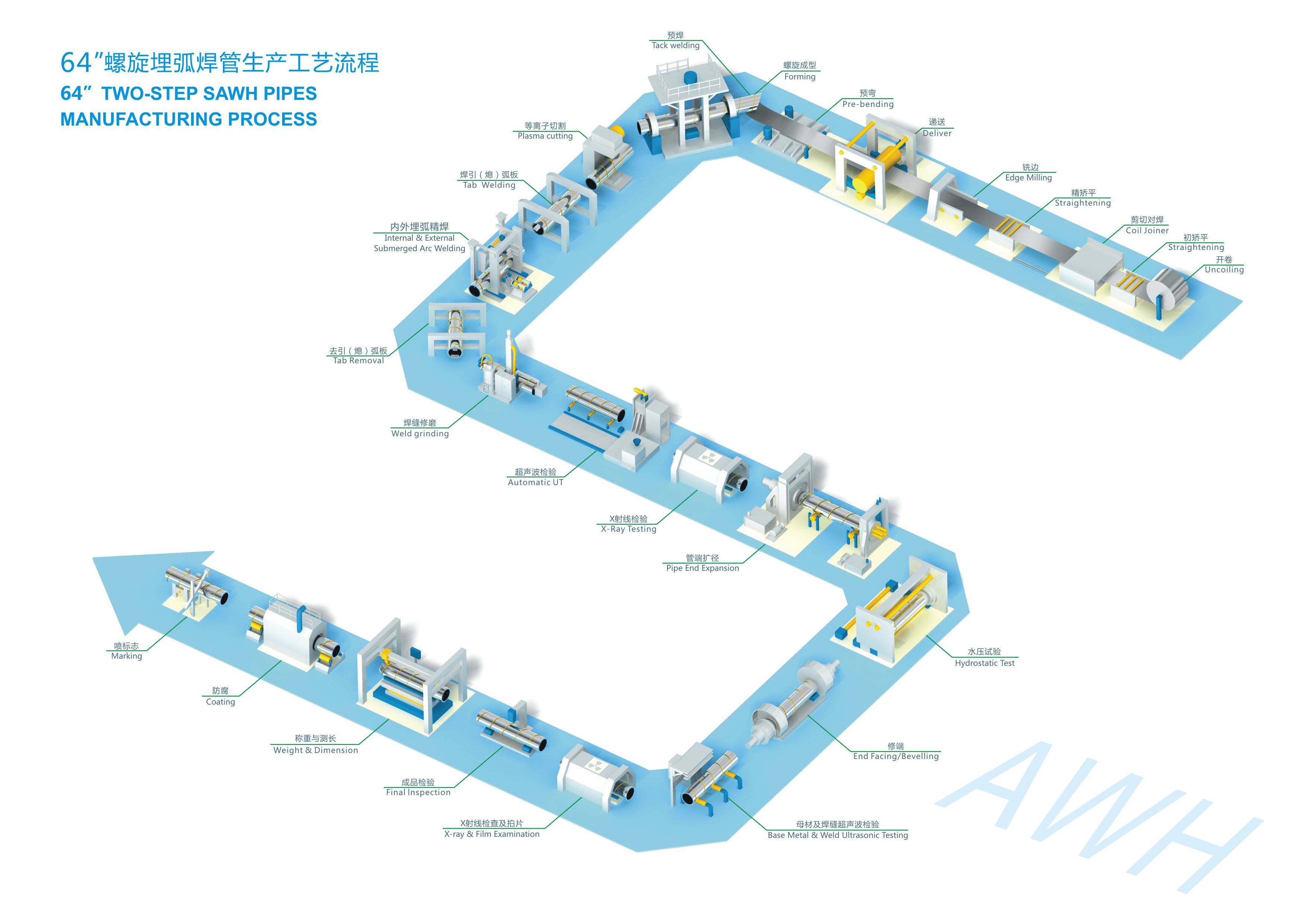

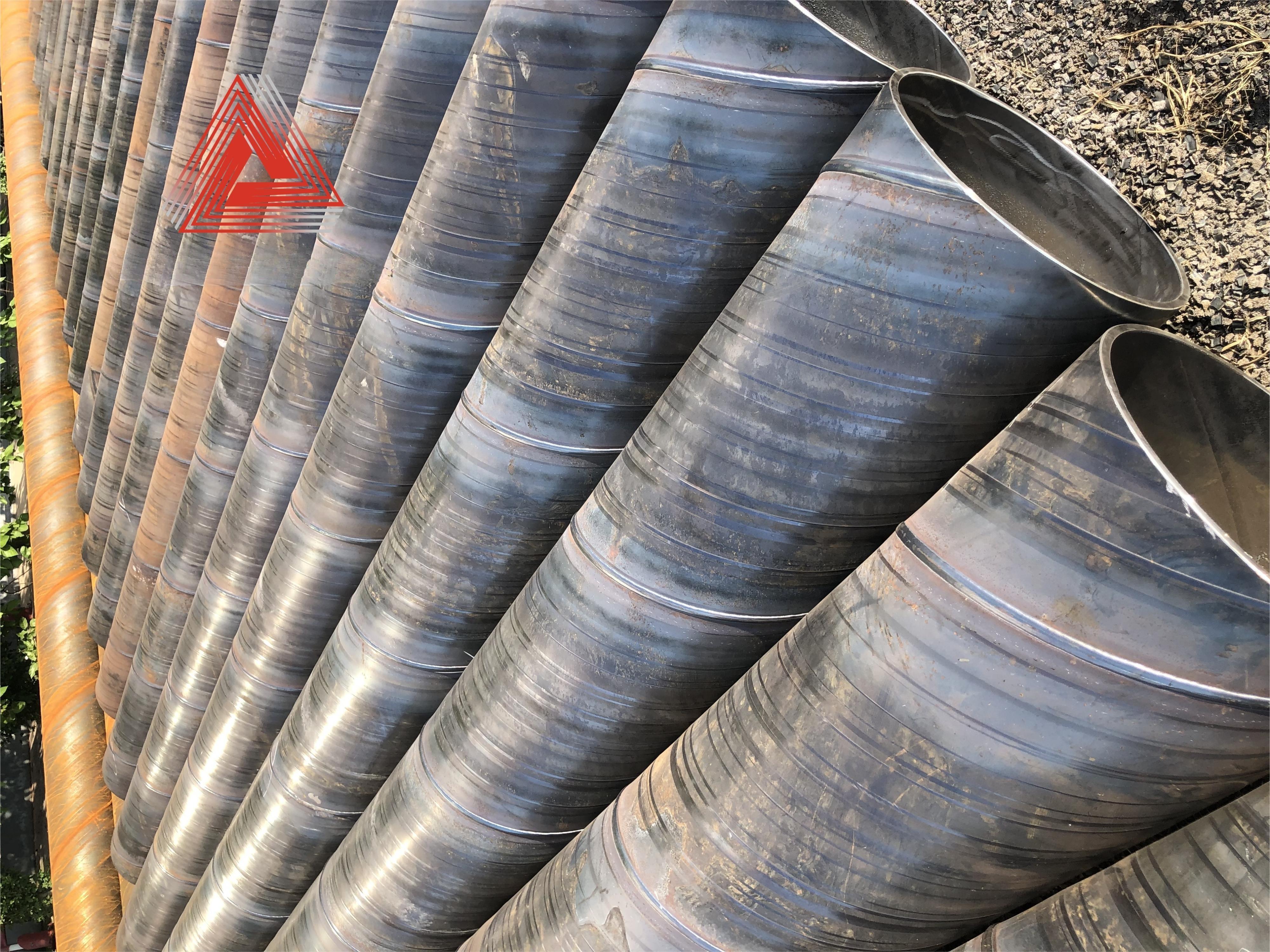

SSAW steel pipe, also known as spiral submerged arc welded steel pipe, is a spiral welded steel pipe produced by double-sided submerged arc welding. Spiral welded pipes are formed using narrower sheets or hot rolled coils, which greatly reduces their production costs. The spiral welding process allows the production of large diameter pipes suitable for transporting large quantities of oil and gas.

Standard

PRODUCT | SSAW STEEL PIPE, SPRIAL STEEL PIPE, SPRIAL WELDED PIPE |

STANDARD | API 5L PSL1/API 5L PSL2/EN10217/EN10219/EN10208 |

/ASTM A53/ASTM A252 Grade 1/2/3, AN/NZS 1163 | |

MATERIAL | Q235B/GR.B/X42/X56/X60/X70/X80/Grade 1/2/3, C350 |

OUTDIAMETER | 219MM-4064MM |

THICKNESS | 3.2MM-40MM |

SURFACE TREATME NT | VARNISH |

BARE PIPE | |

BLACK PAINTING | |

RED PAINTING | |

3LPE | |

YELLOW JACKET | |

GALVANIZATION | |

PACKING | BREAK BULK |

BUNDLE | |

END TREATMENT | PLAIN END |

BEVELED END | |

BSP THREAD WITH COUPLING | |

NPT THREAD WITH COUPLING | |

GROOVED | |

END PROTECTORS | PLASTIC CAPS |

STEEL PROTECTORS | |

MOQ | 1 TON |

APPLICATION | PILLING SUPPORT |

BRIDGE SUPPORT | |

PUBLIC INFRASTURE SUPPORT PIPE | |

DRILLING PIPE | |

OIL AND GAS TRANSPORTATION | |

SEWAGE TRANSMISSION | |

EQUIPMENT MACHINE MADE PIPE | |

PRODUCTION ABILITY | 600,000 TONS |

BUSINESS TYPE | MANUFACTURER OF STEEL PIPE AND STEEL PIPE STOCKIEST |

Manufacturing Process

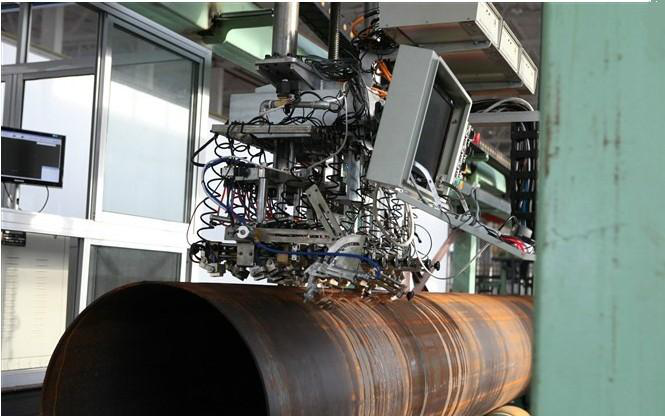

| SSAW steel pipe in the production process, we need to pay attention to a series of matters. Except for the following test items, according to the API standard and other relevant standards and the special requirements of some users, but also the need for steel, steel pipe and other tests Destructive tests, including physical and chemical properties of the raw materials into the plant sampling, visual inspection of 100% steel .

|

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add