Seamless Carbon Steel Pipe

Introduction

Seamless steel pipes are derived from solid steel that is in sheet or bar form and is formed into a solid round shape known as “billets” which are then heated and cast over a form such as a piercing rod to create a hollow tube or shell.

Standard

ASTM A53 Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

ASTM A106 Gr.B | Seamless carbon steel for high temperature service |

ASTM SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

ASTM SA192 | Seamless carbon steel boiler tubes for high pressure |

ASTM SA210 | Seamless Medium-carbon boiler and superheater tubes |

ASTM A213 | Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

ASTM A333 GR.6 | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

ASTM A335 P9,P11,T22,T91 | Seamless ferritic alloy-steel pipe for high-temperature service |

ASTM A336 | Alloy steel forgings for pressure and high-temperature parts |

ASTM SA519 4140/4130 | Seamless carbon for mechanical tubing |

API Spec 5CT J55/K55/N80/L80/P110/K55 | Seamless steel pipe for casing |

API Spec 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70 | Seamless steel pipe for line pipe |

DIN 17175 | Seamless steel tube for elevated temperture |

DN2391 | Cold drawn seamless prevision pipe |

DIN 1629 | Seamless circular unalloyed steel tubes subject to special requirements |

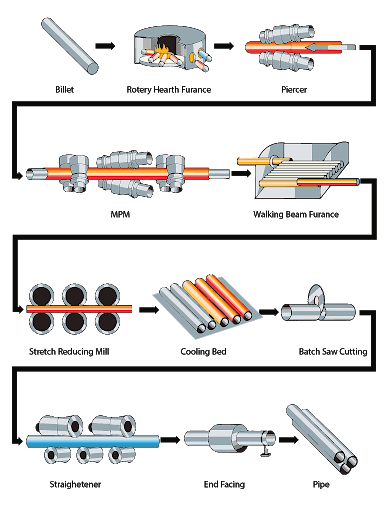

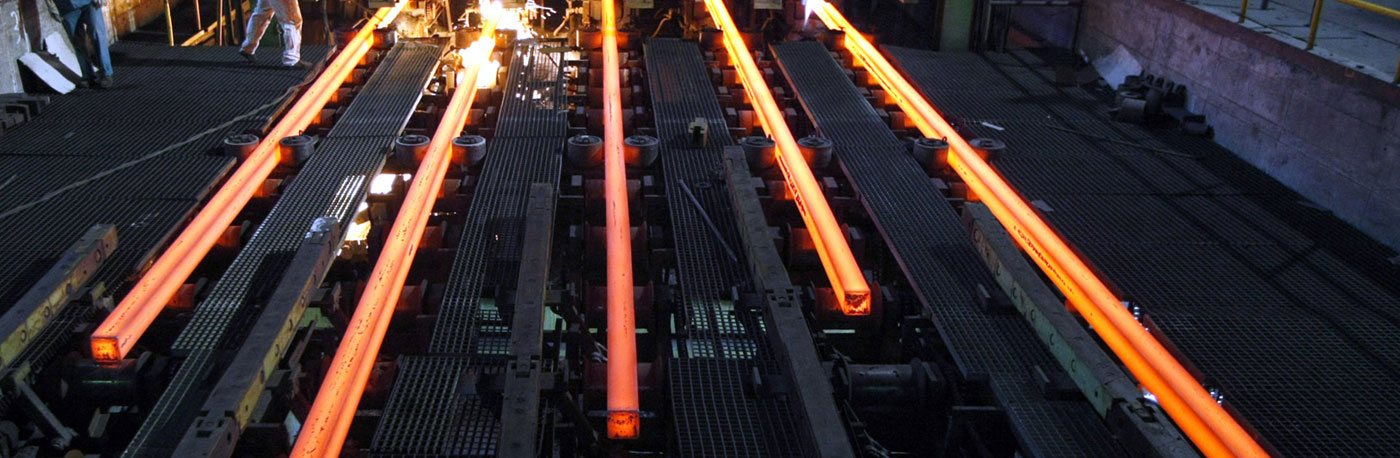

Manufacturing Process

| Billets and coils are delivered to the pipe mill ready to be made into carbon steel pipe. Depending on the capabilities of the pipe mill and the end use of the final product, the casts will be formed into pipe by means of four distinct different manufacturing. Seamless carbon steel pipe has, as its name implies, no longitudinal weld seam. It is, in essence, one solid homogeneous piece of steel. A solid billet is simply heated and then stretched over a series of mandrels until the pipe has achieved its desired diameter and wall thickness. |

Inspection

Non-destructive testing (RT, UT, MT or PT) Heat treatment execution, if specified. Metallographic examination, if applicable. Visual and dimensional control. Hydrostatic test, if applicable. Painting, coating, marking and color coding check. Final visual inspection including packaging and quantity control. |  |

Package

| Plastic caps plugged at the two sides of pipe ends Should be avoided by the steel strapping and transport damage Bundled signs should be uniform and consistent The same bundle(batch) of steel pipe should be came from the same furnace. The steel pipe has the same furnace number, the same steel grade, the same specifications. |

Application

Seamless carbon steel pipes are extensively applied in the nuclear device, gas conveyance, petrochemical, shipbuilding and boiler industries, with characteristics of high corrosion resistance combined with suitable mechanical properties.

- Nuclear device - Gas conveyance - Petrochemical industries - Shipbuilding and boiler industries |  |

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add