SSAW Steel Pipe

Introduction

SSAW steel pipe, also known as spiral submerged arc welded steel pipe, is a spiral welded steel pipe produced by double-sided submerged arc welding. Spiral welded pipes are formed using narrower sheets or hot rolled coils, which greatly reduces their production costs. The spiral welding process allows the production of large diameter pipes suitable for transporting large quantities of oil and gas.

Standard

PRODUCT | SSAW STEEL PIPE, SPRIAL STEEL PIPE, SPRIAL WELDED PIPE |

STANDARD | API 5L PSL1/API 5L PSL2/EN10217/EN10219/EN10208 |

/ASTM A53/ASTM A252 Grade 1/2/3, AN/NZS 1163 | |

MATERIAL | Q235B/GR.B/X42/X56/X60/X70/X80/Grade 1/2/3, C350 |

OUTDIAMETER | 219MM-4064MM |

THICKNESS | 3.2MM-40MM |

SURFACE TREATME NT | VARNISH |

BARE PIPE | |

BLACK PAINTING | |

RED PAINTING | |

3LPE | |

YELLOW JACKET | |

GALVANIZATION | |

PACKING | BREAK BULK |

BUNDLE | |

END TREATMENT | PLAIN END |

BEVELED END | |

BSP THREAD WITH COUPLING | |

NPT THREAD WITH COUPLING | |

GROOVED | |

END PROTECTORS | PLASTIC CAPS |

STEEL PROTECTORS | |

MOQ | 1 TON |

APPLICATION | PILLING SUPPORT |

BRIDGE SUPPORT | |

PUBLIC INFRASTURE SUPPORT PIPE | |

DRILLING PIPE | |

OIL AND GAS TRANSPORTATION | |

SEWAGE TRANSMISSION | |

EQUIPMENT MACHINE MADE PIPE | |

PRODUCTION ABILITY | 600,000 TONS |

BUSINESS TYPE | MANUFACTURER OF STEEL PIPE AND STEEL PIPE STOCKIEST |

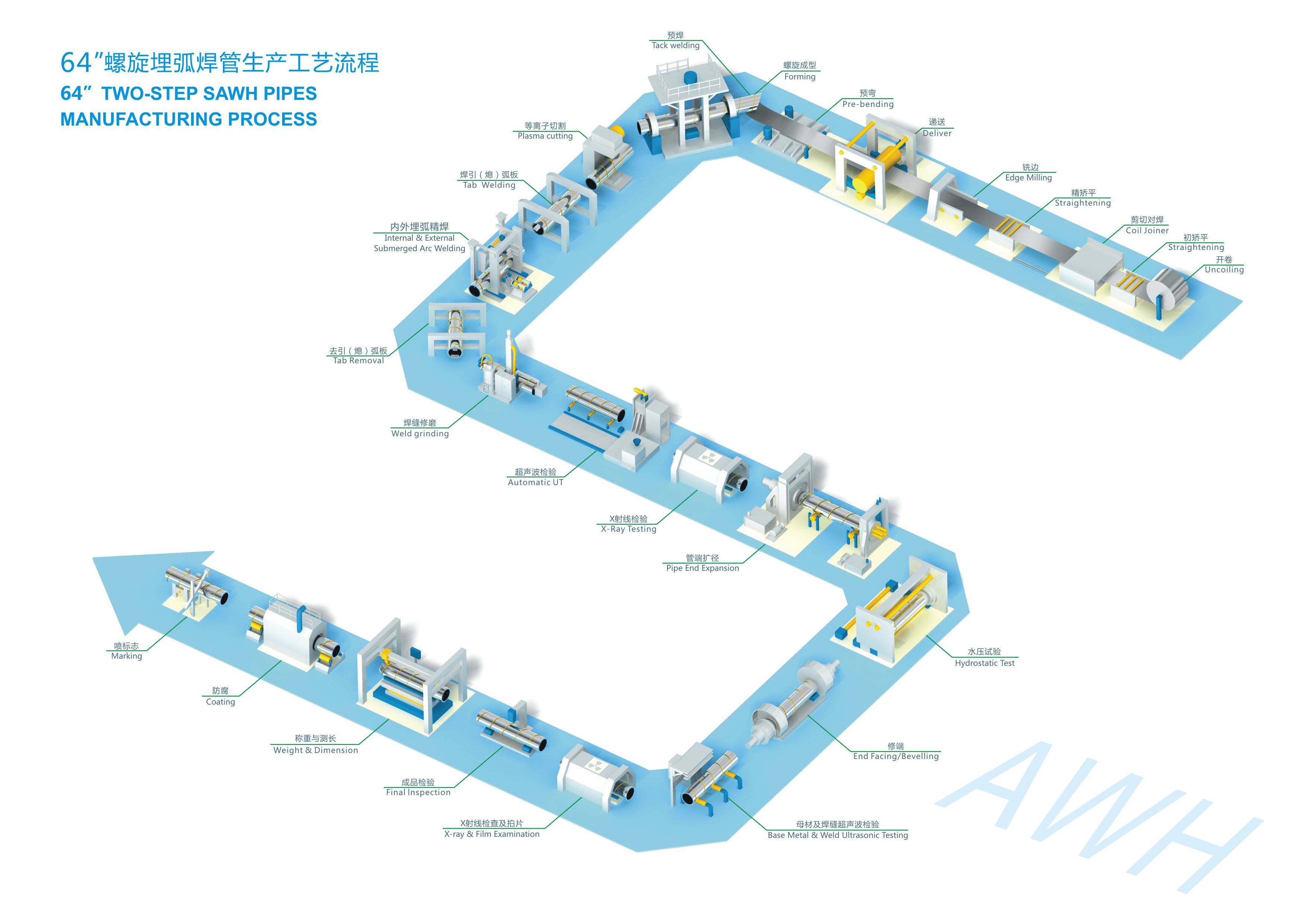

Manufacturing Process

| SSAW steel pipe in the production process, we need to pay attention to a series of matters. Except for the following test items, according to the API standard and other relevant standards and the special requirements of some users, but also the need for steel, steel pipe and other tests Destructive tests, including physical and chemical properties of the raw materials into the plant sampling, visual inspection of 100% steel .

|

Email: admin@pmcsteels.com

Email: admin@pmcsteels.com Tel/WhatsAPP/Wechat

Tel/WhatsAPP/Wechat Add

Add